Receiving ISO Certification symbolizes the dedication O. Keller Tool employees and management have to providing our customers a quality product, as well as quality service.

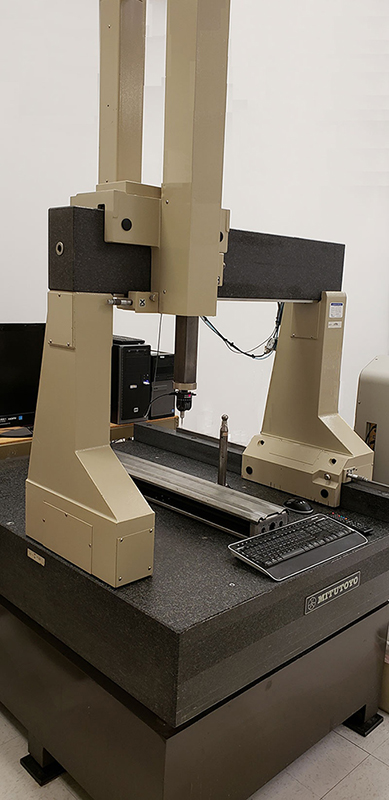

Our climate-controlled Inspection Lab is outfitted with the latest high-tech equipment and is utilized throughout the manufacturing process. From the day customer specifications are received to the shipment of completed orders, the quality of your job is assured by integrated quality control checks and inspections. Our commitment to quality dictates our processes and procedures.